Contact

VICTORY TECHNOLOGY

HL: 86-769-8507 7000

Fx: 86-769-8531 3421

Monica: 86-13829137016

86-13925827222

Attn.: Ms Monica

monicachao@xinkeju.com

Add: Dalang Town,Dongguan City,GD.CN.

Solder Paste Mixing Equipment

Double planetary homogenous mixer

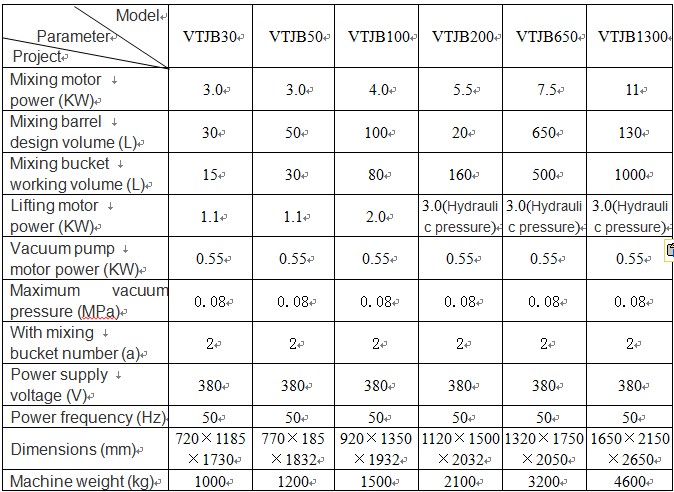

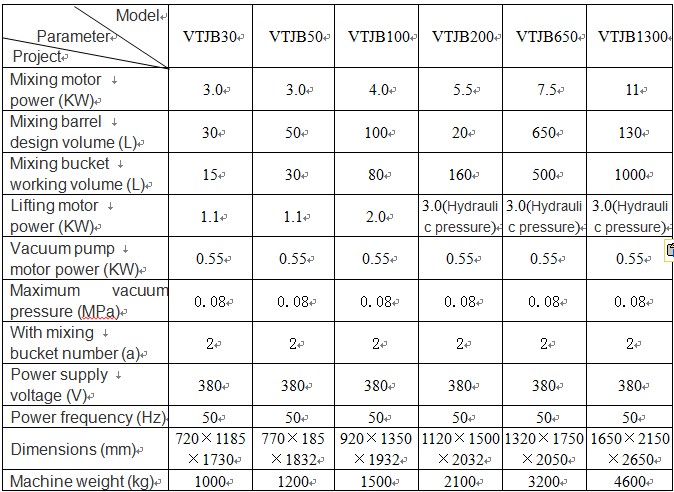

1. Parameters:

2.Description:

The double planetary mixer is a set of reactions, mixing, kneading homogenizing into one versatile and efficient products, widely used in battery paste, medicine cream, cosmetic cream, paste food, electronics solder paste and other body kinds of paste, slurry stirred.

This series of double planetary mixer is from the upper beam, the plane seat, square column, lifting mechanism, lifts and straight track, on the barrel, mixing bucket, vacuum pump, buffer tank, transmission, electric control cabinet and operation panel other components

A stirring tank: two-layer structure, barrel body jacket, inside and outside lamps with 304 # stainless steel, jacketed spoiler, bottom of the barrel jacket, bottom of the barrel pulleys 4, barrel body with handles. After turning deflector jacket, uniform cooling of the cooling water barrel materials, ensure that the material process temperature uniformity. The flange surface and the barrel inner face by turning to ensure that the tube wall and the gap is in two-cage small range, so that all the materials are thoroughly stirred barrel.

2 throwing cage: There are two specially designed stainless steel precision casting curve modeling stir cage, the cage rotates between the two regions staggered stir in the double planetary transmission driven by two throwing cage with the carrier for both the revolution, while for each rotation, so that the barrel material is sufficiently stirred.

3 on the barrel: the barrel is 304 stainless steel, is a component of the seal chamber, on a vacuum line and vacuum gauge, illuminated windows, observation window.

4 Transmission: planetary gear transmission principle, to achieve two throwing cage and carrier to 0-50RPM speed of revolution at the same time, each for speed 0-100RPM rotation. Transmission system adopts inverter control revolution and rotation speed.

5 Vacuum system: mixing drum with the barrel between the barrel and frame between the drive shaft and frame are made between the seal design, dynamic seal with mechanical seals, static seals with silicone rubber O- pieces. Vacuum pump rotary vane vacuum pump, so that the barrel material in a vacuum environment to achieve mixing, mixing of materials to meet specific process requirements.

6 Lift system: screw jacks, lifts, linear guide components for conveying mixing bucket lift, easy mixing, filling and discharge.

7 Control system: stirring speed controlled by frequency conversion; mixing bucket with planet carrier rotates together with the thermocouple temperature measurement means for controlling the temperature of the barrel material; mixing bucket positioning, up, down both proximity switch control and a safety interlock logic control, a safe sound and light alarm.

大安市|

宣武区|

松江区|

仁布县|

石柱|

长春市|

镶黄旗|

龙胜|

新乡县|

高平市|

临沭县|

扎赉特旗|

米易县|

南通市|

区。|

本溪市|

瓮安县|

乌拉特前旗|

荆州市|

江达县|

银川市|

东兰县|

上犹县|

温泉县|

大田县|

科技|

乌兰浩特市|

林西县|

额尔古纳市|

象山县|

田东县|

青阳县|

昆明市|

冀州市|

鹿泉市|

大悟县|

临海市|

峡江县|

四会市|

句容市|

东乡族自治县|